Laboratories

Mechnical Sciences Lab

This lab has two divisions one deals with Fluid Mechanics and Thermodynamics and the other with Applied Mechanics. In the first, experiments being conducted are mainly based on the determination of discharge and other parameters using Bernoullis theorem and continuity equation. Equipment under this section include Orificemeter, Venturimeter, Rotameter, Pope friction apparatus, laminar flow appratus and notch apparatus. All apparatus are closed - circuit type. In the section of Applied Mechanics, experiments are performed to understand the basic theories of Applied Mechanics. Some of the related instruments include screw jack, worm and worm wheel, bell crank lever, simply supported beam etc.

This laboratory has all the basic facilities to conduct experimental work related to mechanics, fluid mechanics and thermodynamics. Experiments based basic principles related to force/stresses on structure; Bernoulli's theorem, Nature of Laminar and Turbulent flow, friction in the pipes; Thermodynamics and Power cycles are conducted. The laboratory also makes use of different modern flow measuring devices. Efforts are being made to upgrade some conventional equipment with modern computer assisted devices.

Kinematics and Dynamics of Machines (KDM) Lab

This laboratory is developed to imbibe practical hand in the subject of Theory of Machines and Mechanisms. Here students get practical exposure of following mechanisms and experiments:

- CAM Analysis Machine

- Generation Involute Gear

- Inversion of four bar chain

- Elliptical Trammel

- Whirling of shaft apparatus

- Static and Dynamic balancing

- Motorized Gyroscope

- Universal Governor· Vibration Analysis Equipment

- Epicyclic Gear Train and Torque holding Apparatus

- Slip and Creep Measurement

- Coriollis Component of Acceleration

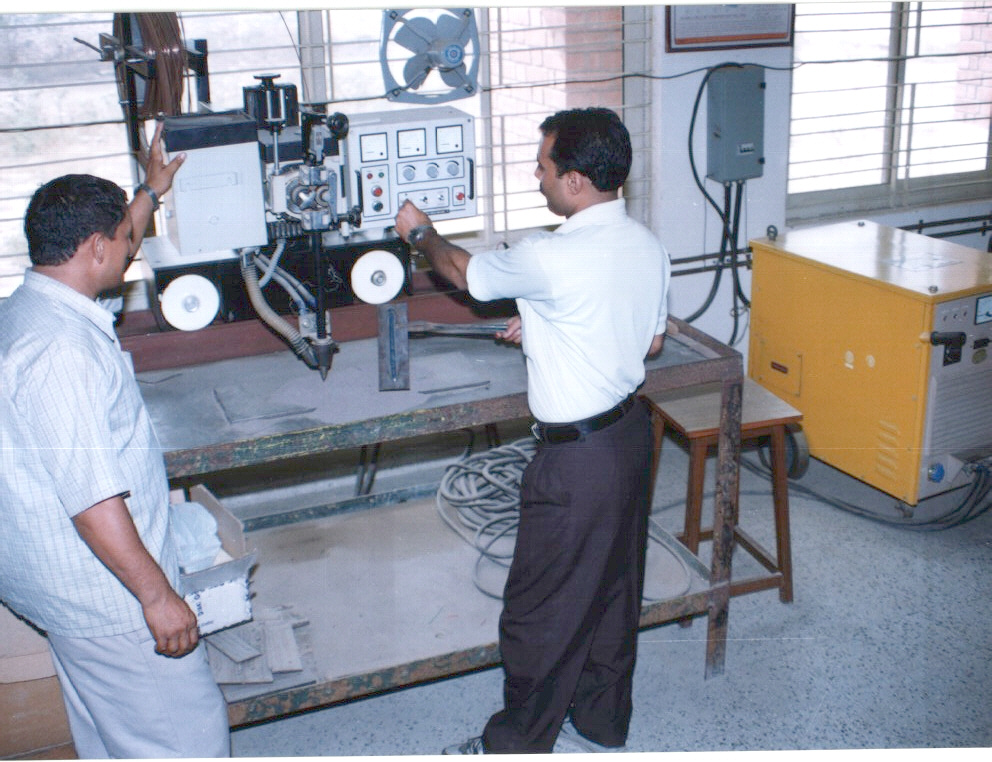

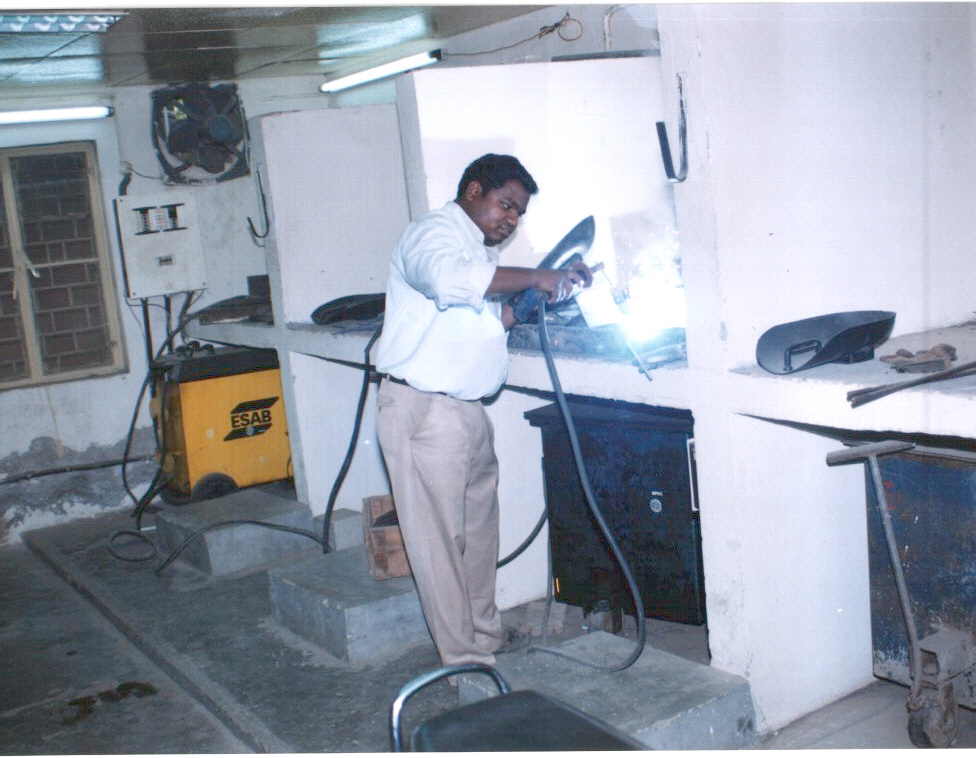

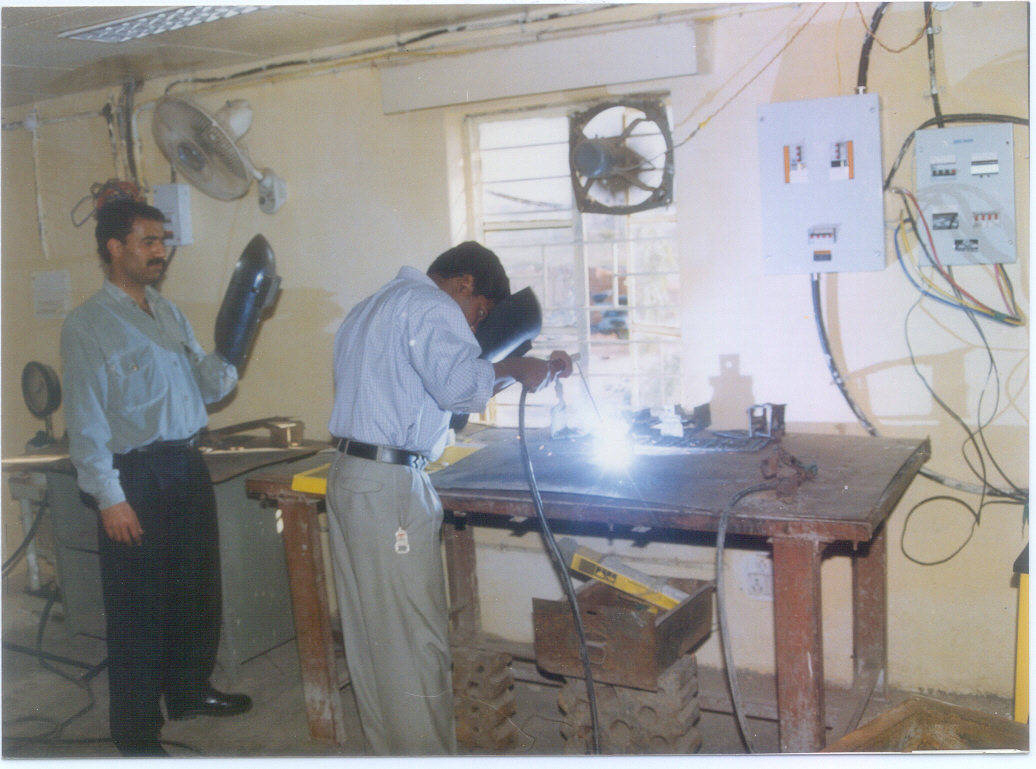

Welding Lab

A welding lab has been established which is equipped with an Automatic Submerged Arc Welding unit and Automatic Metal Inert Gas (MIG).

Materials Testing Lab

A Material Testing Lab. has been established to provide facilities for testing of material. Presently the lab is equipped with Vickers hardness testing, Rockwel Hardness testing, Impact Testing, Erichsen Testing Machines, and Tensile Testing Machine.

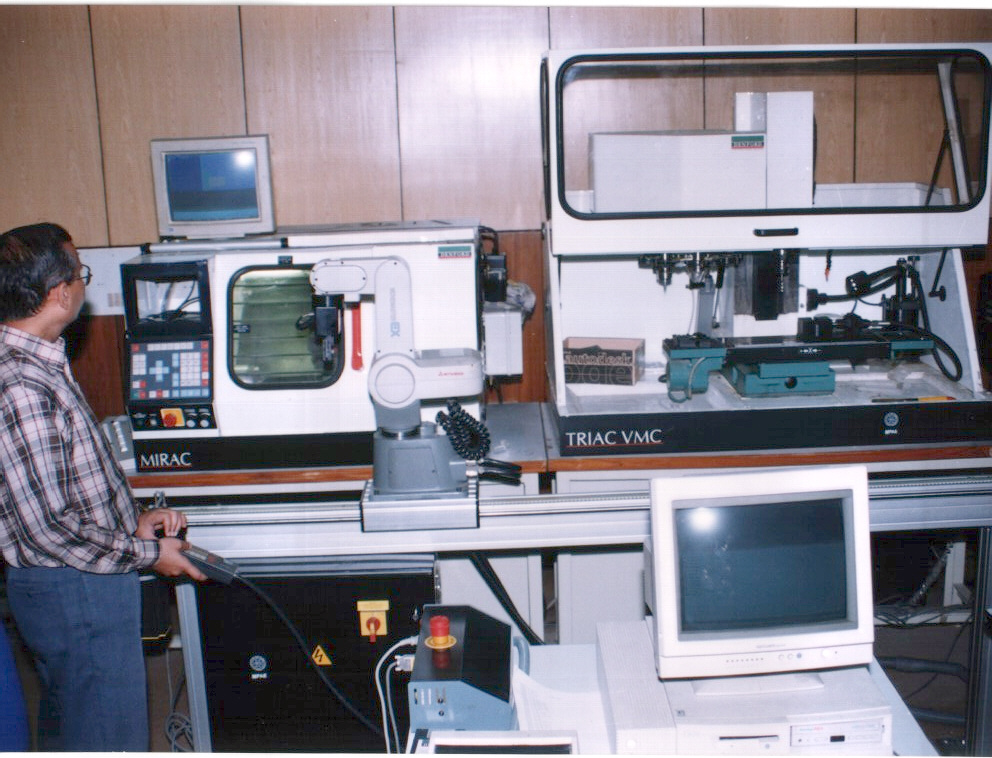

Flexible Manufacturing System (FMS) and Computer Integrated Manufacturing (CIM) Lab

This laboratory has two trainer CNC machines (Denford, U.K.), a Mitsubishi Robot having 5-degrees of freedom, a linear slide on which robot moves and other supporting equipment. Students get hands-on experience in programming and working with CNC machines, robot and linear slide for the robot, completely integrated under a control of single computer. A host computer uses information in an integrated manner to create a fully automated shop floor. Besides this, hardware type experiments with Software simulation provides unique opportunity to the students to understand the principles and design involved. Some training programmes in the area of "Operation And Programming Of CNC Machines " have also been organized for the industrial and other institution personnel during the last few years.

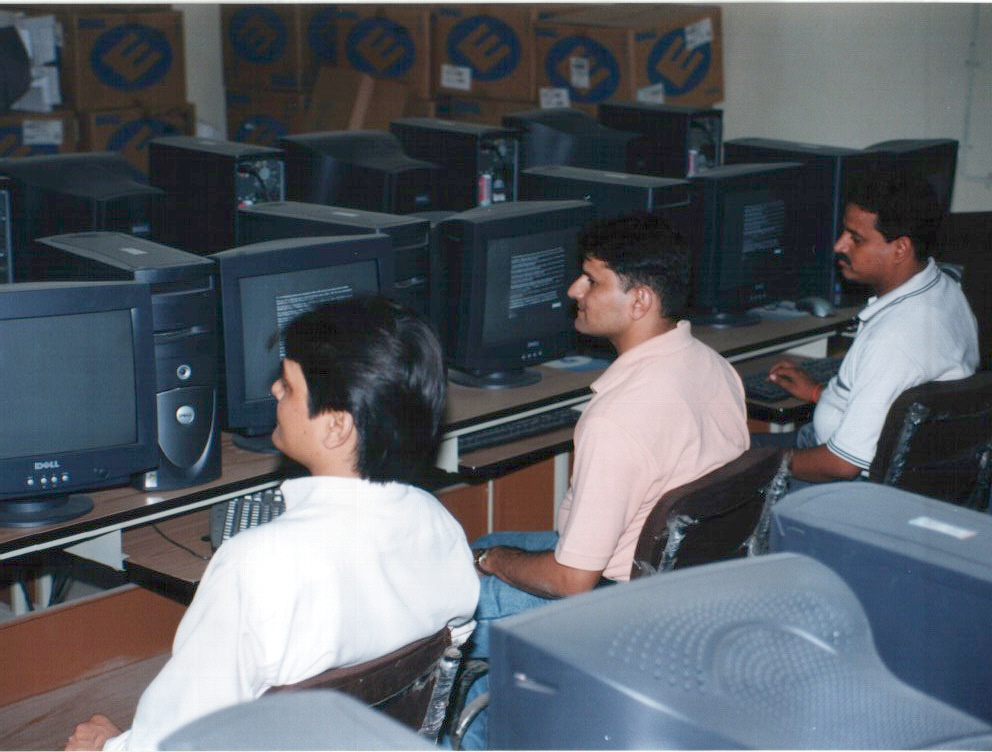

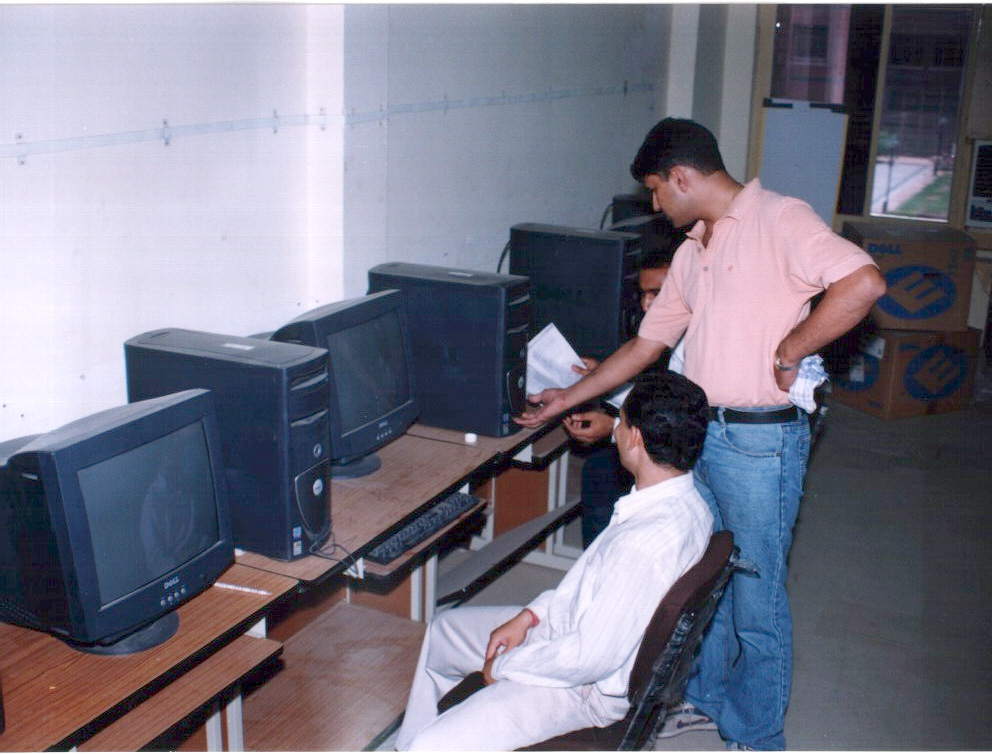

CAD/CAM/CAE Lab

Objective of this laboratory is:- Imparting students with practical knowledge of latest design to manufacturing and tooling practices.

- Emphasize & teach the importance of analysis driven design process for better productivity.

- Industry relevance to enhance career opportunities of students.

- Equipping the students with modern tools to facilitate project work.

- Developing NSIT as an engineering consultant.

- Research and Development.

It is one of the most popular laboratories of the institute presently equipped with number of DELL workstations. Laboratory is also equipped with adequate number of peripheral devices such as printers, projectors, scanner, plotters etc.

Some of the best software such as NX, CATIA for mechanical design, analysis and automation applications are being used by the undergraduates, which offer excellent employability in India as well as abroad.

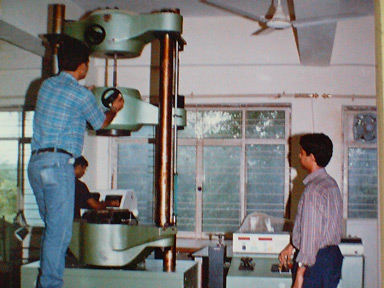

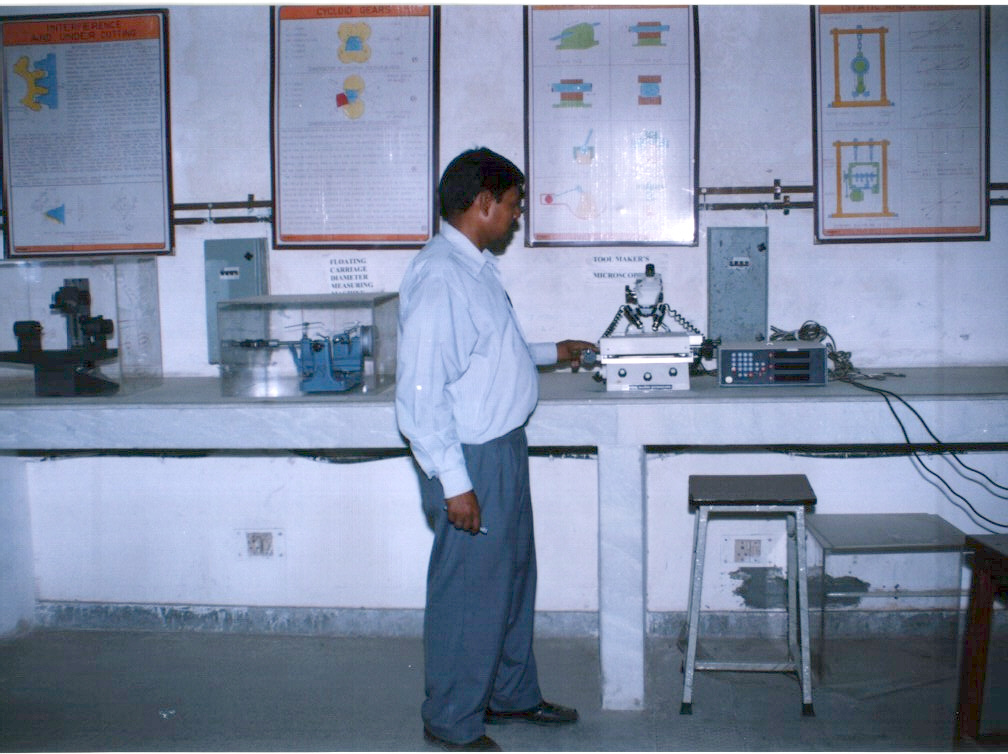

Metrology Lab

The aim of this laboratory is to make the students understand the importance of precision measurements. In view of its industrial relevance, Metrology laboratory has special importance in engineering education. In this laboratory exposure to work on high precision measuring instruments is provided, to make the students familiar with principles, operation and application of measuring techniques. The laboratory is equipped with following equipments: -

- Profile projector

- Floating carriage diameter measuring machine

- Tool maker's microscope

- Slip and angle gauges

- Complete range of hand held precision measuring instruments

- Electronic and pneumatic gauges

Efforts are being made to continuously upgrade the laboratory by the induction of other sophisticated instruments to broaden the scope of work in the laboratory for R&D work.

Central Workshop Lab

Presently there are four shops besides the Machine Tools Lab.

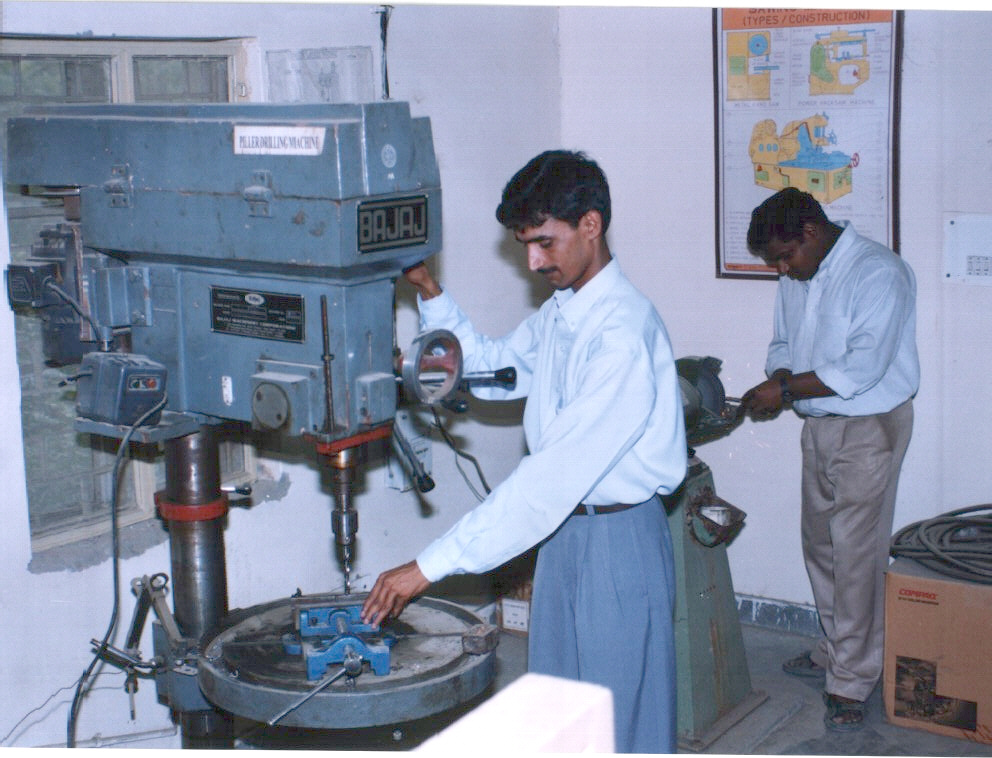

Machine Shop

It has semi automated lathes, millers, cutters and grinders. Experiments are designed in such a way that student get a feel of actual working condition.

Fitting Shop

All fitting tools are available for training the students. Drilling, Power Saw and grinding units are also installed to serve as ancillary units to facilitate work connected with cutting, drilling and grinding.

Welding Shop

A well-equipped welding shop has been established with facilities for Electric Arc and gas welding. Flame cutting unit is also available.

Sheet Metal Shop

A sheet metal shop has been established but with limited facilities at present. However, it is expected to augment these shortly.

Foundry Shop

A Foundry Shop with update facilities for Sand testing and machine molding installed in it. Melting and di casting facilities are also available.

Sand Testing Lab

Sand Testing Lab